Phone: +86 18801508111

+86 13861024040

Email: zc@tayacn.com

Wesley.Wu@tayacn.com

Tel: +86 519-88911555

Fax: +86 519-88902486

E-mail: zc@tayacn.com

Pharmaceutical industry

WDG pesticide water dispersion granule production line

Detailed description

Overview

Granules (Granule or GR) are referred to as granules, and granular preparations processed by additives such as original drugs and carriers. The earliest field trials of granules began in 1946, and were widely used in the United States in the early 1950s. In the early 1960s, Japan began to use it in large quantities. Due to the development of environmental science in the late 1960s, pesticide granules have been widely used throughout the world in order to avoid contamination of the environment and crops by particle drift during pesticide powder spreading. The development of granules in China was mainly in the late 1970s. In 1989, the Ministry of Chemical Industry statistic granules accounted for about 7% of the total pesticide preparation.

The reason why granules can become a commonly used pesticide is because it has many unparalleled characteristics:

1. It has directionality when applied, so that the spreading agent can reach the target organism sufficiently and it is safe for natural enemies;

2 attached to the stems and leaves of plants, to avoid direct contact phytotoxicity;

no dust ③ when spraying, do not pollute the environment;

④ during spraying can be reduced operator body attachment or inhaled dose, to avoid poisoning;

⑤ the high- Poisonous pesticides are low-toxic, avoiding poisoning of humans and animals;

6 can control the release rate of active ingredients in granules and prolong the duration

of use ; 7 easy to use and high efficiency.

In summary, the pesticide water dispersible granules (WDG). The International Federation of Pesticide Industry Associations (GIFAR) defines it as: granules used after disintegration and dispersion in water. The water-dispersible granule is mainly composed of an active ingredient of a pesticide, a dispersing agent, a wetting agent, a binder, a disintegrating agent and a filler, and has a particle diameter of 200 μm -5 mm, and can rapidly disintegrate and disperse after entering water to form a high suspension dispersion system.

Based on first-class technology and rich experience in production, Jiangsu Sunchen Drying Engineering Co., Ltd. has not designed and improved innovation. At present, it has designed a new special production line for WDG pesticide water-dispersible granules, which fully meets the market's dust-free and easy-to-use pesticides. Disintegration, easy transportation and other requirements, has become the most famous WDG production line in China, and has dozens of engineering cases for users to visit and certify.

Our company can carry out engineering design according to the actual requirements of users. At present, the output of single production line is 100kg/h, 200kg/h, 300kg/h, 500kg/h, 800kg/h, etc.

Equipment Characteristics

of WDG Pesticide Water Dispersible Granule Production Line 1. The WDG Pesticide Water Dispersible Granule Production Line adopts the form of integrated crushing, mixing, granulating, drying, cooling, sieving and packing sections. It has clear functions and can be organically combined and co-ordinated. Run to achieve process flow.

2. The core part of the production line: the drying system. Adopting the method of sectional heating, the pre-drying section adopts the high-pressure low-air volume fan to make the wet WDG particles completely fluidized; the drying section adopts the low-pressure and high-volume fan, taking away more water per unit time and drying evenly; The high air volume fan can quickly remove heat and reduce the temperature of the product, which not only meets the requirements of moisture control, but also facilitates the subsequent packaging process.

3. Dry medium circulation system: The blower, heater and air inlet duct are made of stainless steel to avoid the possibility that the product will be contaminated by unclean wind.

4. The quick-opening structure between the upper and lower beds of the drying host changes the traditional structure by bolts and connects the form, which greatly facilitates the thorough cleaning of the system.

5. The hole type of the paving bed plate adopts a combined structure, and the front section adopts a tongue-shaped hole, so that the material can smoothly move forward without causing leakage; the middle end uses a straight hole, and the hot air has a higher penetration rate and is dry. The heat exchange of the process is more complete.

6. The inside of the lower bed body is made of stainless steel full-welding, which avoids the sewage entering the insulation layer when washing, thus affecting the product quality, and also has a cleaning port to facilitate cleaning equipment.

WDG pesticide water dispersion granule production line process and production equipment:

production process 1: weighing ingredients → mixing (ZGH vertical high speed mixer) → granulation (ZL rotary granulator) → drying (XF boiling) Dryer)→Sieving (ZS, FS type vibrating screen)→Loading (ZKS vacuum feeding machine)→Packaging

production process 2: Weighing ingredients→One-step method (XLB type cyclone granulating coating machine)→Sieving (ZS type oscillating screen) → loading (ZKS vacuum feeding machine) → packaging

Equipment introduction in the production process: Features of the ZGH vertical high-speed mixer equipment of WDG production line

◆ The centrifugal force formed by the vertical high-speed rotating blades installed at the bottom of the machine body acts on the material to make the outer surface roll upwards, and the center is sunken downward. The swirling shape makes the inner and outer rings of the material and the upper and lower layers fully stirred and mixed;

◆ The high-speed scraping blades installed on the side wall of the machine are used to break up the material that is rolled up by the outer ring, and at the same time, it acts as a disturbance. The relative movement between large materials improves the mixing effect;

◆ Due to the joint action of the above two kinds of blades, the material can achieve the purpose of sufficient and uniform mixing in a short time, and the efficiency is difficult to compare with other domestic mixers. the;

◆ mixing bin without dead angle, fast discharge, easy to clean;

◆ machine material contact parts are made of stainless steel, the mixing process does not produce volatile material, deterioration or loss phenomena, the process of matching security requirements;

WDG line Features of ZL rotary granulator

This machine is made of stainless steel when it comes into contact with materials. It has beautiful appearance and reasonable structure. The pellet forming rate is high, the particles are beautiful, the material is automatically discharged, the particle breakage caused by manual discharging is avoided, and the water flow operation is suitable.

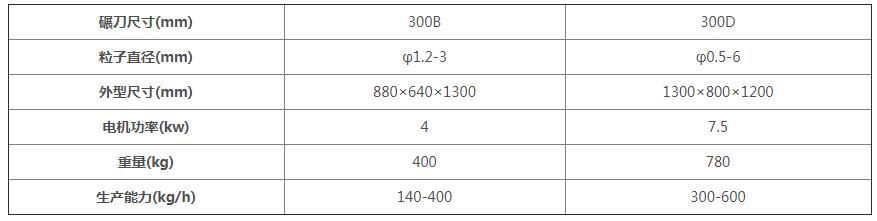

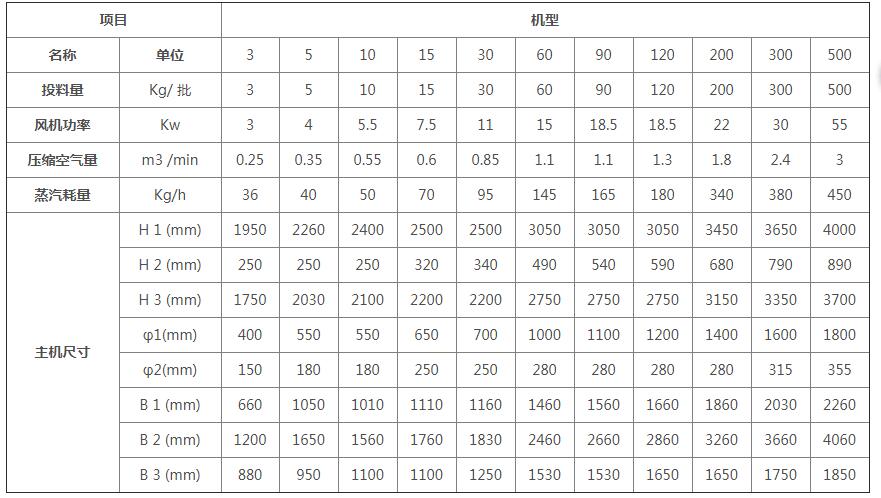

Technical Parameters

WDG production line XF boiling dryer working principle

Clean hot air is distributed into the bed through the valve plate. The wet material entering from the feeder is fluidized by hot air. If boiled boiling water jumps in the bed, it is called boiling dryer. Or machine), because the hot air is in wide contact with the material, it can be dried in a short time. Entering from one end of the bed, after a few minutes to tens of minutes of "boiling", automatically flows out from the other end of the bed.

Installation instructions The

fluidized bed, cyclone separator and bag filter are placed on a flat concrete floor without the need for foot screws. Fans can be installed indoors or outdoors, with base and anchor screws. The floor plan can be adjusted as appropriate depending on the plant.

The duct system should be airtight so as not to affect the drying effect.

Heating mode

steam or electric heating, hot air can also be directly obtained from the hot air furnace of fuel (or coal).

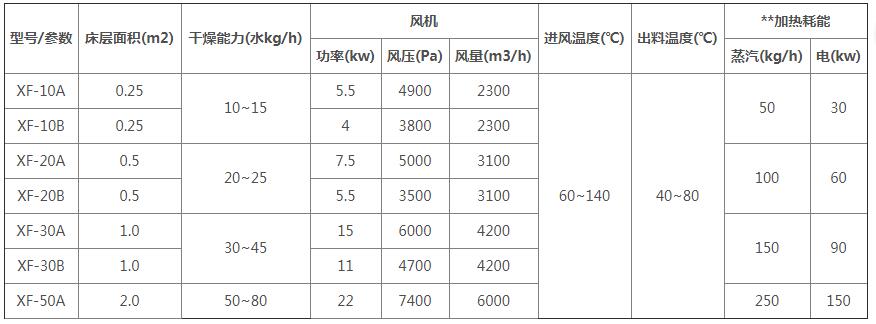

The main technical parameters

WDG production line ZS, FS type oscillating screen structure features

This machine is composed of hopper, oscillation chamber, coupling and motor. The oscillating chamber has an eccentric wheel, a rubber cushion, a main shaft, a bearing, etc. The adjustable eccentric weight is transmitted to the spindle center line by the motor drive, and in the equilibrium state, a centrifugal force is generated to change the material strength to form an orbital vortex in the sieve. The amplitude of the weight controller can be adjusted according to different materials and screens.

The whole machine has compact structure, small volume, no dust, low noise, high quality, low energy consumption, convenient movement and maintenance.

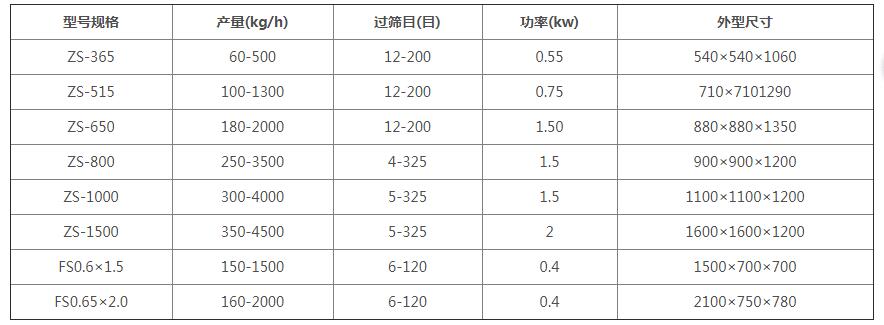

Technical Parameters

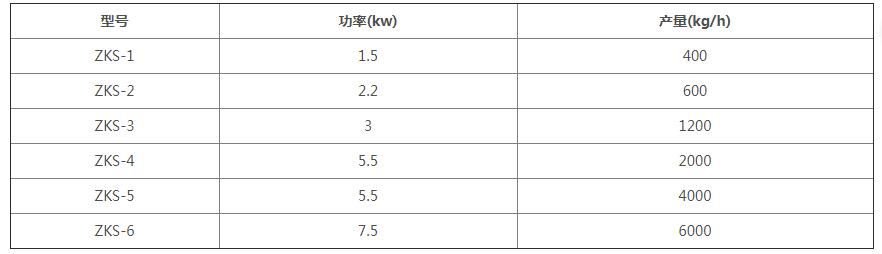

WDG production line ZKS vacuum feeder overview

ZKS vacuum feeder, also known as vacuum conveyor, is a dust-free closed pipeline conveying device that transfers particles and powder materials by means of vacuum suction, using the pressure difference between vacuum and environmental space. The gas flow in the pipeline is formed to drive the movement of the powdery material, thereby completing the transportation of the powder.

WDG production line XLB type cyclone granulator coating machine features

◆ Fluidized bed air distribution plate is made into a special ring-shaped structure, each piece forms a layered form, allowing airflow from the gap of the blade to form a circulating high-speed airflow. Thereby, the material is in a swirling regular motion, and the adhesive or coating liquid is sprayed into the regular flow material layer through a pneumatic nozzle mounted on the side wall, thereby granulating the powder or obtaining a continuous uniform film coating.

◆ Special structure air distribution plate, which forms regular movement of materials, and solves the problem of channel flow and dead angle.

◆ The prepared granules are porous, fast-dissolving, and have a certain strength, high density, and are not easily broken.

◆ Materials with poor moisture absorption and poor fluidity can also be made into qualified particles.

Technical Parameters

Prev:没有上一篇

关注我们

关注我们