Phone: +86 18801508111

Email: zc@tayacn.com

Tel: +86 519-88911555

Fax: +86 519-88902486

E-mail: zc@tayacn.com

Drying equipment series

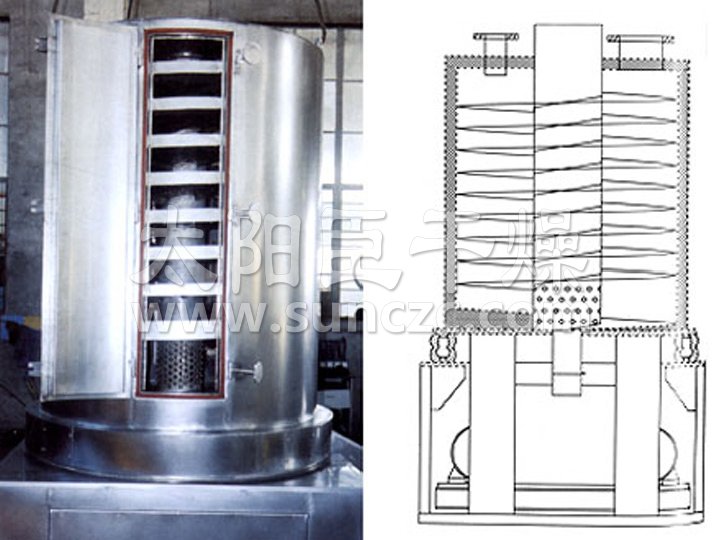

LZG series spiral vibration dryer

Detailed description

Product Overview The

wet material enters the spiral bed from the top feeding port. Under the effect of the circumferential excitation force and gravity, the material moves from top to bottom along the spiral bed until the bottom layer; at the same time, the clean hot air enters from the bottom of the spiral bed. After thorough heat transfer and mass transfer with the materials distributed on the bed, they are discharged from the top of the vents. In order to achieve the purpose of drying the material.

Application

The drying equipment is mainly used for the drying of traditional Chinese medicine pills. It can also be applied to the drying of granular, short strip, and spherical materials in the industries of chemical engineering, control, food, plastics, building materials, and feed.

Main Features

● The hot air passes through the material layer several times and the material flows in the opposite direction, so that the heat exchange is sufficient and the thermal efficiency is high.

● Compact structure, small footprint.

● The residence time of the material in the bed can be adjusted and the operation is convenient.

● The material moves along the spiral bed from the bottom to the top while making a jump on itself, which increases the contact between the material and hot air and enhances the drying effect.

● Continuous feeding and discharging are suitable for assembly line operations, and are easy to meet the “GMP” standard, which can replace the traditional box drying.

● There is no damage to the surface and shape of the material, which not only ensures the roundness of the pill, but also greatly reduces the breaking rate of the pill.

Technical specifications

| model | LZG-1.0 | LZG-1.2 | LZG-1.4 | LZG-1.6 | LZG-1.8 |

| Diameter (mm) | 1,000 | 1200 | 1400 | 1600 | 1800 |

| Vibration motor power (kw) | 2×1.1 | 2×1.1 | 2×1.5 | 2×1.5 | 2×2.2 |

| Overall size (m) | 1.2 x 1.2 x 2.7 | 1.4×1.4×2.7 | 1.6×1.6×3.3 | 1.8×1.8×3.3 | 2.0×2.0×3.3 |

| Weight (kg) | 1400 | 1680 | 2800 | 3100 | 3800 |

| Inlet air temperature (°C) | 60-200 | 60-200 | 60-200 | 60-200 | 60-200 |

| Air volume (m3/h) | 1487 | 2380 | 3721 | 4462 | 5930 |

Prev:没有上一篇

关注我们

关注我们