Phone: +86 18801508111

Email: zc@tayacn.com

Tel: +86 519-88911555

Fax: +86 519-88902486

E-mail: zc@tayacn.com

Drying equipment series

GFG Series Efficient Boiling Dryer

Detailed description

Working principle After the

air is heated and purified, it is introduced by the induced draft fan from the lower part and passes through the hole net plate of the hopper. In the working chamber, the fluidization is formed by stirring and negative pressure. After the moisture evaporates rapidly, the material is quickly dried as the exhaust gas is carried away.

Performance features

◎ fluidized bed is a round structure to avoid dead ends.

◎ Stirring is set in the hopper to prevent the formation of channel flow when the wet material is agglomerated and dried.

◎Using tipping and unloading, it is convenient, rapid and thorough, and it can also design automatic feeding and discharging system according to requirements.

◎ Sealed negative pressure operation, air flow filtered. Easy to operate, easy to clean.

◎ Drying speed, temperature uniformity, each batch of drying time is generally 20-30 minutes, depending on the material.

To adapt to the material

◎ mechanism screw extrusion particles, rocking particles, wet high-speed mixing granulation particles.

◎ Drying of wet granules and powdered materials in the fields of medicine, food, feed, and chemical industry.

◎ large particles, small pieces, sticky block granular materials.

◎ Konjac and other materials that change in volume when dried.

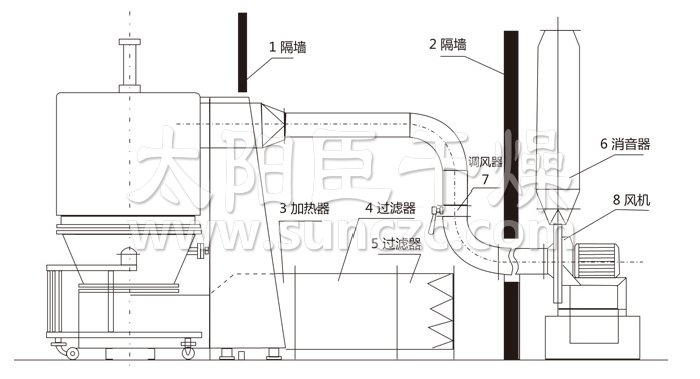

Schematic

Technical specifications

| project | model | ||||||

| Feeding (kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Fan power (kw) | 7.5 | 11 | 15 | 18.5 | twenty two | 30 | 45 |

| Stirring power (kw) | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | 2.2 |

| Stirring speed (rpm) | 8 to 11 | ||||||

| Steam consumption (kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Operation time (min) | 15-30 (based on material properties) | ||||||

| Host height | 2700 | 2900 | 2900 | 2900 | 2900 | 3300 | 3500 |

关注我们

关注我们