Phone: +86 18801508111

Email: zc@tayacn.com

Tel: +86 519-88911555

Fax: +86 519-88902486

E-mail: zc@tayacn.com

Drying equipment series

ZLG series vibration fluidized bed dryer

Detailed description

Working principle The

material enters into the machine from the feed inlet. Under the action of vibration force, the material is thrown along the horizontal fluidized bed and continuously moves forward. After the hot air passes through the fluidized bed and exchanges heat with the wet material, the humid air passes through the cyclone separator. Dust removal by exhaust 1:3 discharge. Dry material is discharged from the discharge inlet.

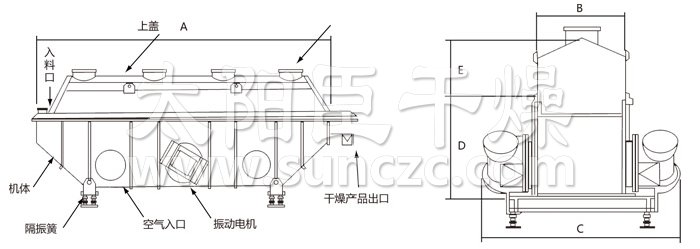

Schematic

Adaptable materials are

suitable for the drying and cooling of powdery and granular materials in the chemical, pharmaceutical, food, dehydrated vegetables, food, minerals and other industries. Such as: citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, radish, soybean meal, distiller's grains, seeds, slag, sugar and so on.

Performance characteristics

◎Vibration source is driven by vibration motor, smooth operation, convenient maintenance, low noise, long life.

◎ Fluidized and uniform, no dead space and blow-through phenomenon, uniform drying and cooling products can be obtained.

◎Adjustability is good and width is applicable. The layer thickness and the speed of movement in the machine and the change of the full amplitude can achieve stepless adjustment.

◎ damage to the surface of the material is small. It can be used for the drying of fragile materials. When the material particles are irregular, it will not affect the work effect.

◎ Adopt fully enclosed structure. Effectively prevent cross-infection between materials and air, and clean the operating environment.

◎ High mechanical efficiency and thermal efficiency, good energy-saving effect, energy saving 30-60% compared to general drying equipment.

Technical specifications

| Size / Model | A | B | C | D | E | F | Weight (kg) |

| ZLG3×0.30 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| ZLG 4.5×0.30 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| ZLG 4.5×0.45 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| ZLG4.5×0.60 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1670 |

| ZLG6×0.45 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 2100 |

| ZLG6×0.60 | 6000 | 600 | 1700 | 1,000 | 500 | 1700 | 2410 |

| ZLG6×0.75 | 6000 | 750 | 1850 | 1,000 | 600 | 1850 | 2840 |

| ZLG6×0.9 | 6000 | 900 | 2000 | 1,000 | 600 | 1850 | 3160 |

| ZLG7.5×0.60 | 7500 | 600 | 1850 | 1,000 | 600 | 1850 | 3200 |

| ZLG7.5×0.75 | 7500 | 750 | 2000 | 1,000 | 600 | 1850 | 3600 |

| ZLG7.5×0.9 | 7500 | 900 | 2100 | 1,000 | 600 | 1850 | 4140 |

| ZLG7.5×1.2 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

| model | Fluidized bed area (M2) | Inlet temperature ( o C) | Outlet temperature ( o C) | Evaporation capacity (kg) | Vibration motor | |

| model | Power Kw | |||||

| ZLG3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| ZLG4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| ZLG6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| ZLG6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| ZLG6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| ZLG6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.60 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| ZLG7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

| ZLG7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0×2 |

★ Above evaporation is the maximum evaporation.

关注我们

关注我们